Wisconsin-based company providing $100,000, plus expertise to support student innovation

Jerry Poling

October 27, 2022

National and worldwide efforts to improve sustainability in the plastics industry are receiving a boost from UW-Stout, thanks to a major donation by EVCO Plastics.

The Wisconsin-based company, which has 12 facilities in two states and two foreign countries, has given $100,000 to the university’s plastics engineering program. The money will be used to help students conduct sustainability research, including providing materials for their projects.

EVCO Chairman and CEO Dale Evans told students to “change the world” recently when he visited campus to make the donation and learn about their research in the Plastics Engineering Labs.

“We’re happy to give back. Too many different materials go into the waste stream. We’re trying to fix that and further the success of engineering students and the plastics industry as a whole,” said Evans, a 1973 UW-Stout graduate in industrial technology.

The company, with headquarters in DeForest, has supported the UW-Stout program for more than a decade. It also is providing students access to EVCO experts during the research process to help answer technical questions and “to deepen and support their knowledge and understanding. Our goal is to catalyze more processor industry investment in this space,” Evans said.

Promoting sustainability is one of the goals of UW-Stout’s plastics engineering program, said Professor Wei Zheng.

“We are grateful for the continuous support from EVCO. In fact, this is the first donation we have received that specifically focuses on the plastics recycling. The funding will surely propel us to investigate the challenges and opportunities of various recycling technologies,” said Zheng, program director.

“More importantly, the research will help us incorporate more sustainability into our curriculum to educate the next generation workforce. Together, we hope to make a difference in today’s world,” she added.

Graduates from the program report an average starting salary of $66,000 with 100% employment. It’s one of four undergraduate engineering programs and a graduate program in UW-Stout’s Robert F. Cervenka School of Engineering.

The donation was announced recently at K 2022, a worldwide plastics conference held in Dusseldorf, Germany. An opening keynote address by German government minister Christiane Rohleder urged the industry to significantly increase its use of recycled plastic in products to reduce dependence on fossil fuels, Plastics News reported. “We need to move from a still relatively linear economy to a truly circular economy of plastics,” she said.

Anna Evans Bartz, EVCO director of communications, agreed.

“As processors, we believe that our involvement in developing and nurturing a circular economy is paramount to future sustainability success. EVCO also recently launched its Sustainability Council, which focuses on both internal sustainability initiatives and providing actionable green solutions to customers. The results and output of the funded research at UW-Stout will inform the solutions and recommendations we pass along to customers.”

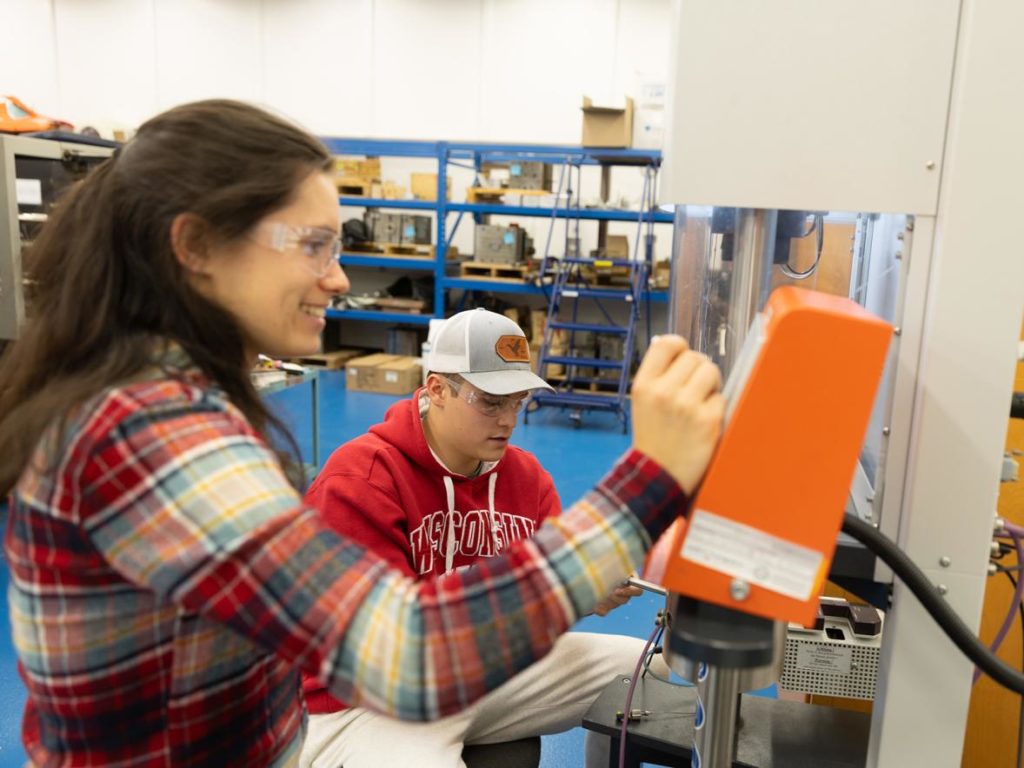

The funding will help support five senior capstone projects by UW-Stout students that research the viability of using recycled materials in plastics products.

EVCO hopes the projects have commercial value to help provide solutions for new, more sustainable product options for their customers. “Sustainability efforts often are dictated by the customer,” Bartz said.

Read more about the donation in Plastics News.

The UW-Stout student projects include:

Development of Novel Highway Sound Barriers Using Post-Consumer Recycled (PCR) Material

Objective: Design and develop a highway sound barrier with a PCR composition that can be easily assembled and manufactured, while adhering to any codes or construction requirements. Initial works will focus on the product design for manufacturability and the development of 3D printed prototypes.

After molding the scaled models, the products will be tested for effective sound reduction, mechanical integrity, weathering ability and other properties.

The project will showcase a direct application of recycled materials into consumer products and highlight the sustainability efforts.

Reverse Crosslinking of a Green Thermosetting Resin

Objective: Investigate the reverse cross-linking modes of a thermoset polyester.

If suitable means of reverse cross-linking can be identified, the same chemical cross-linking group can be used to modify other types of polymers, making it possible to develop materials with new properties but maintaining the same reverse cross-linking ability afterward.

The research results would transform the science and technology of plastics recycling, making previously nonrecyclable polymers recyclable.

Characterization and Processing of Virgin and PCR Materials

Objective: Study various properties of PCR and virgin materials and examine their molding process.

Physical, thermal, mechanical and rheological behavior of the PCR material will be fully characterized and compared with the virgin counterpart. The collected material parameters will be incorporated into a simulation software to simulate the process, providing guidelines to the molding operations.

The products made of the PCR and virgin materials will be evaluated in terms of the thermal and mechanical performance. This project aims to broaden the knowledge base of PCR materials in the industry and provide insights to plastics processors to better handle the recycled materials.

About EVCO Plastics

EVCO Plastics is a leading plastics manufacturing company with 12 manufacturing facilities strategically located throughout the world. With an emphasis on design for manufacturability, strategic engineering and innovative technology, EVCO is recognized as a global leader in custom plastic injection molding.

EVCO was founded in 1964, employs more than 2,000 people and operates 270 injection molding machines, ranging from 28 to 4,400 tons. For more information about EVCO, visit LinkedIn, or YouTube.

###